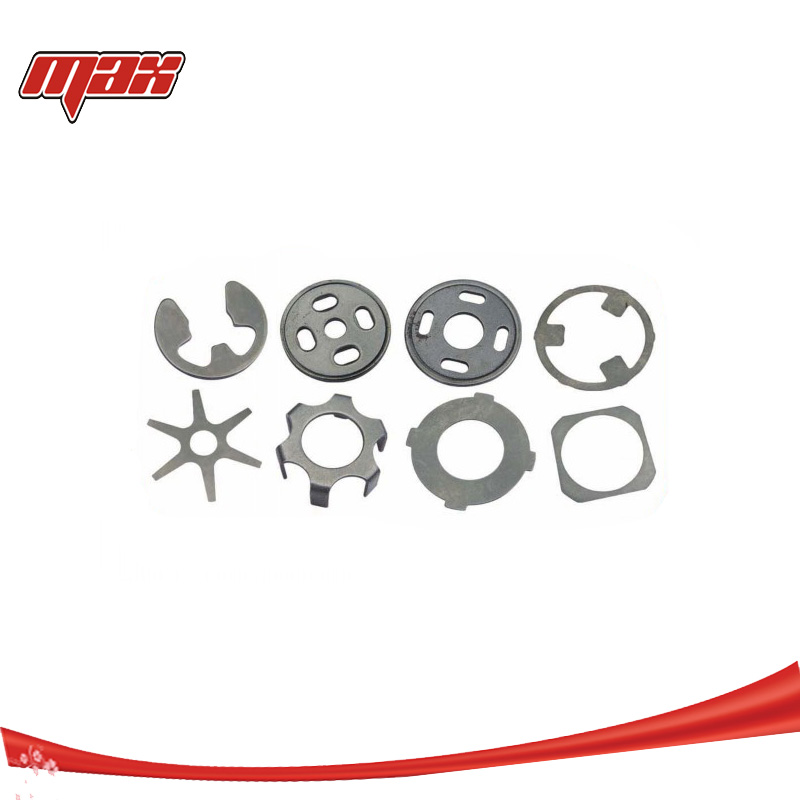

Powder Metal Sintered Part base valve bakeng sa Shock Absorber

Likarolo tsa sehlahisoa:

Piston le valve e tlase haholo-holo li fana ka damping bakeng sa moferefere oa ho ts'oha, tataiso ea lithupa haholo-holo bakeng sa motsamao oa piston rod.

Max Auto ke moetsi ea holimo oa metallurgy ea matlalikarolo tse sintered, haholo-holo e sebelisoa bakeng sa likarolo tse thibelang ho tšoha .

Ts'ebetso ea thekenoloji: ho kopanya phofo - ho etsa - ho sintering - ho hloekisa -Ho phekola ka mouoane - Ho kokota-Press bushing-Tlhahlobo ea ponahalo, ho paka.

Ho kopanya phofo: Fe - C - Cu phofo ka sieve e phahameng ea density ho tlosa litšila, mochini o kopanyang o ikemetseng oa 360 ° o potoloha lihora tse fetang 4, etsa hore thepa e kopane ka mokhoa o ts'oanang.

Ho bopa: hlobo e nepahetseng e nang le mochini oa "hydraulic press" oa CNC ho netefatsa hore boholo ba likarolo tsohle bo finyella litlhoko tsa ts'ebetso ka mor'a ho hatella.

Sintering: sehlahisoa se laoloa ke sebōpi sa letlooa la mofuta oa sintering, se tiisang hore thepa ea mechine le boima ba lihlahisoa ho finyella litlhoko tsa tekheniki.

Ho qoelisoa ka oli: beha sehlahisoa ka har'a sejana se nang le khatello e phahameng e le hore oli e ka kenella ka ho feletseng ka har'a li-pores tsa sehlahisoa le ho qoba mafome a potoloho ea morao.

Plastiki: hlobo e nepahetseng e nang le mochini o ikemetseng oa CNC hydraulic press, boleng ba sehlahisoa le thepa ea mochine e ntlafatsoa le ho feta ka mor'a ho hatella, 'me litekanyo li finyella litlhoko tsa setšoantšo.

Machining: qeta lesoba, groove le lintlha tse ling tsa sehlahisoa.

Ho hloekisa: lebanta la mesh le nka mochini o hloekisang oa ultrasonic ho tlosa litšila le lithapo tsa tšepe.

Phekolo ea mouoane: sehlahisoa se tšoaroa ka mouoane ka sebōping sa motlakase, se ntlafatsang thepa ea mochine oa sehlahisoa, 'me karolo ea holim'a oxidation e thusa ho thibela mafome.

Ho paka: piston e koahetsoe ke mochini o laolang lipalo o ikemetseng o koahelang lebanta la ho tlotsa la PTFE.

Tobetsa bushing: e hatelloa ho DU bushing.

Tlhahlobo ea ponahalo, ho paka.

Tlhaloso :

| Lintlha tsa Sehlahisoa | |

| Lebitso la Sehlahiswa | Karolo ea Powder Metal Sintered bakeng sa Shock Absorber |

| Lintho tse bonahalang | (MPIF 35) FC-0205 (DIN 30910-4) Sint C10, Fe, Balance, Cu 1.5-3.9%, C 0.3-0.6% |

| Botenya | 6.4-6.9 g/cm3 ka mor'a hore mouoane oxidation |

| Ho thatafala | 60-115 HRB, e kenya 1 kN, bophara ba bolo 1/16 ″ |

| Kalafo ea Bokaholimo | Mouoane oxidation, lihora tse 2, Fe3O4: 0.004-0.005mm, tekanyo ea oxidation 2-4% |

| Mamello e sa Boleloeng | ISO 2768 – m / H14, h14, +- IT14/2 |

| Ponahalo | Ha ho na ho putlama, mapetsong, exfoliation, voids, looseness, tšepe pitting le liphoso tse ling. |

| Phallo ea Ts'ebetso | Ho kopanya phofo - Ho theha - Sintering - Ho kenngoa ha oli - Sizing - Ho hloekisa ka mokhoa oa Ultrasonic - Oxidation ea mouoane - Ho kenngoa ha oli - ho qetela tlhahlobo - (+ DP4 bushing / +PTFE sehlopha) Ho paka |

| Kopo | Bakeng sa mochine o kenang ka koloing, oa sethuthuthu le oa libaesekele |

| Melemo ea rona: | 1. Ho feta mefuta ea hajoale ea 3000, boloka litšenyehelo tsa hau tsa hlobo 2. Setifikeiti sa ISO/TS 16949: 2009 3.Theko ea tlhōlisano 4.Strictly boleng taolo bokgoni ba APQP, FEMA, MSA, PPAP, SPC |

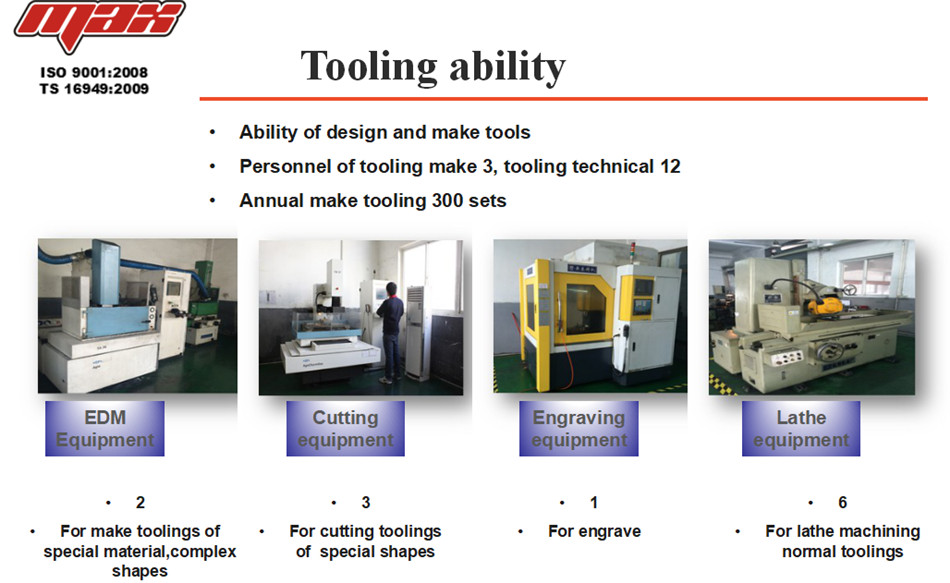

Lisebelisoa tsa Tlhahiso

Litsi tsa Tlhahlobo