Top Manufacturer ea chrome rod ka theko e ntle customized size

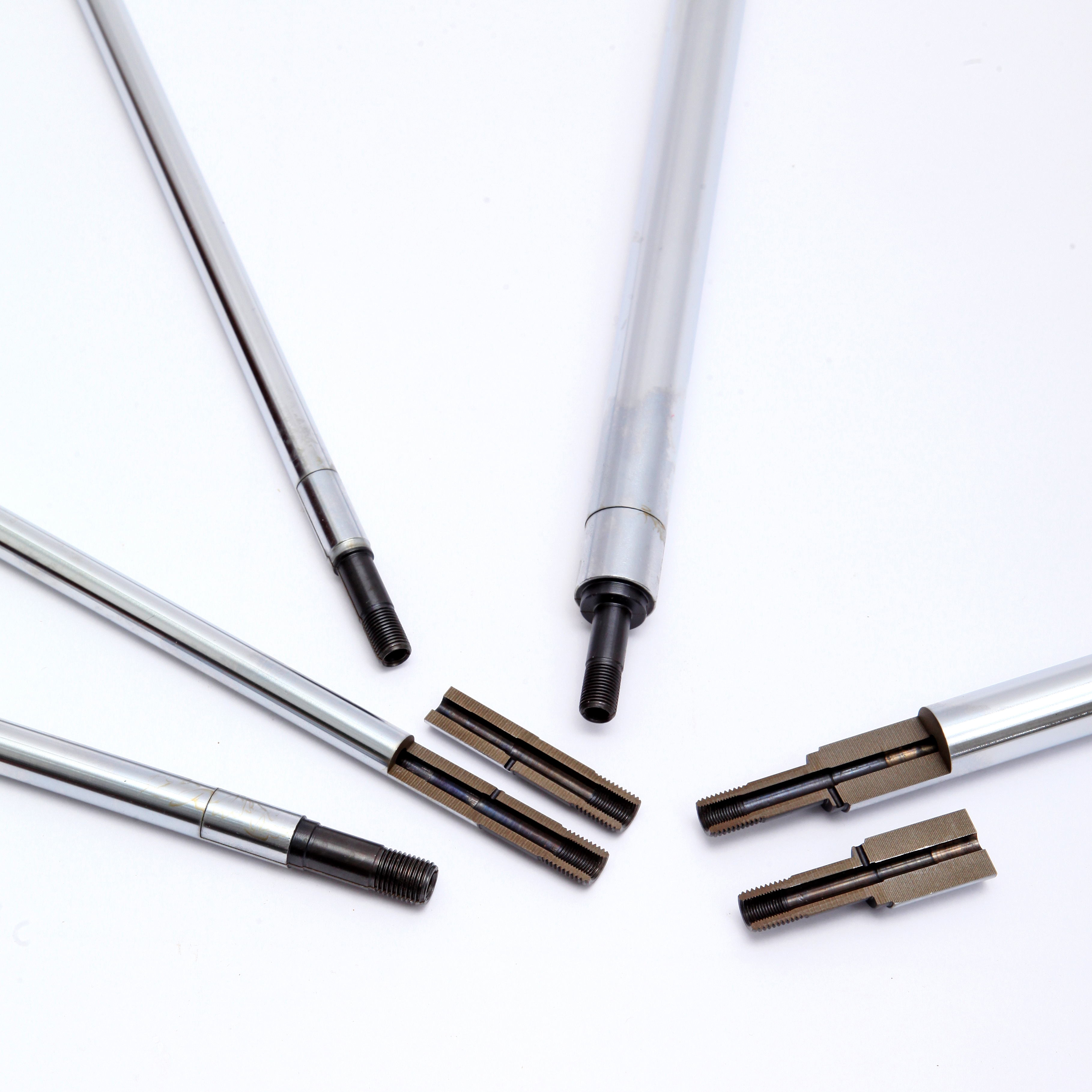

| Kantle Diameter: | Ø 6mm-35mm |

| Kakaretso ea Bolelele: | 100-650 limilimithara |

| Lisebelisoa tsa tšepe: | SAE1035/SAE1045 |

| Botenya ba Chrome: | 10-25 μm |

| Bothata ba Chrome: | 900 HV Min |

| Bokhopo: | Ra 0.1 Micron Max |

| Ho otloloha: | 0.02/400mm |

| Kotulo Matla | Ho ea ka thepa ea tšepe le tlhokahalo ea bareki |

| Matla a tšepe | Ho ea ka thepa ea tšepe le tlhokahalo ea bareki |

| Elongation | Ho ea ka thepa ea tšepe |

| Bend Test | Ho ea ka tlhokahalo ea bareki |

| Boemo ba phepelo: | 1. Hard Chrome Plated |

| 2. Phekolo ea QPQ | |

| 3. Induction Hardened | |

| 4. Dehydrogenation & Tempered

|

Kopo: Molamu oa Piston oa Chrome o sebelisoa haholo ho hydraulic pneumatic, mochini oa boenjiniere, ho etsa likoloi kamolamu oa piston, mochini o tataisang litšiea tsa polasetiki, mochini o pakang, mochini o hatisang, rolara, metjhini ea masela, mochini oa lipalangoang o nang le axis, motsamao oa mola o nang le mola o optical axis.

I. selelekela sa tshebetso.

Themolamu oa pistonE entsoe ka chromium e thata holim'a tšepe ea tšepe e koahetsoeng ka lera le letenya la chromium plating, 'me botenya ba eona bo tloaelehile ho li-microns tse 10 ho isa ho tse 30, ho sebelisoa litšobotsi tsa chromium ho ntlafatsa ts'ebetso ea likarolo, joalo ka ho thatafala, ho se sebetse, ho hanyetsa mocheso le ho hanyetsa kutu.

Likarolo tsa ts'ebetso ea molamu oa piston o thata oa chrome:

1) katleho ea hajoale ea cathode e phahame joalo ka 25% ~ 35%, mme sekhahla sa deposition se potlakile haholo.

2) boima bo phahameng (900 ~ 1200HV), mapetsong a marang-rang a junifomo le a teteaneng, ho hanyetsa ha marang-rang hantle; li-Microcracks li ka hlahisoa, 'me palo ea li-microcracks e ka fihla likotoana tsa 800-2000 / cm (ho ea ka tlhokahalo), le ho ntlafatsa anti- bokgoni ba kutu.

3) bokhoni ba ho qhalakanngoa ha bate ea plating, botenya ba junifomo ea ho roala, ha ho bonolo ho hlahisa ketsahalo ea hlahala e bohale, 'me ponahalo ea chromium lera e khanyang ebile e boreleli;

4) ho roala ho na le matla a matla a ho kopanya le substrate, 'me ho etsoa pele ho tšoana le theknoloji ea setso,' me ts'ebetso e bonolo ho feta mokhoa oa setso;

5) dikahare tsa trivalent chromium ka bateng e lumelloa ho ba bophara, 'me hangata ha ho hlokahale ho khaotsa electrolysis bakeng sa trivalent chromium;

6) tharollo ea plating ha e na fluoride, ha e na lintho tse sa tloaelehang tsa lefats'e, 'me ha ho kutu ea sesebelisoa ntle le matla a tlase.

2. Phallo ea ts'ebetso.

1).Ho phalla ha hydraulic piston rod.

Molamu o kopanyang o sebelisa tšepe ea 35, theknoloji ea ho sebetsa: e batang e etsa hore ho be thata ho etsa hore ho be thata, ho sila ha cylindrical, cylindrical grinding cylindrical e ntle ea ho kuta karolo ea cylindrical ho kuta. E le ho ntlafatsa boleng ba holim'a metsi le ho hanyetsa kutu ea molamu oa piston, mokhoa oa ho qetela oa ho qetela o ile oa eketsoa pele ho plating ea chrome.

2).Mokhoa oa ho roala molamu oa piston.

Tlhahlobo pele ho plating - pakete e leketlileng - ho tlosoa ha lik'hemik'hale, oli ea ho phahamisa motlakase - metsi - activation pickling - ho hlatsoa metsi- motsotsoana, piston rod chromium plating, metsi a sebelisoang hape - ho hlatsoa metsi - ho theola thepa e leketlileng - tlhahlobo